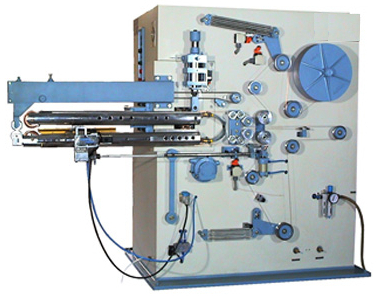

Side Seaming Welding Machine

We are one of the few names to manufacture and export supreme quality Side Seaming Machine. The offered equipment is widely known for its high performance and smooth operation. Confiding on reliable vendors for high-grade metals and alloys, we assure the durability of the whole range of seaming machines offered.

SIDE SEAMING WELDING MACHINE

With the lapse of time, we have gained experience and became proficient in the manufacturing and exporting of high quality Side Seaming Welding Machine. Resistant to corrosion and abrasion, the offered product is highly durable in its features. Our team of quality controllers checks the whole range of products to be offered on various parameters and hence assure the invincible quality of the products.

| SPECIFICATIONS | |

|---|---|

| CAPACITY | 500 ml - 4 ltr | OUTPUT | 40 / 45 per minute |

| NET WEIGHT | 250 Kgs |

| SHIPMENT CASE DIMENSIONS | 66" x 66" x 85" |

features

Durability

Durability

Reliability

Reliability

High performance

High performance

STRECH FORMERS

Mechelonic make Stretch Forming Machine is used for making 18 Litres square containers from circular seam welded containers, with the additional functions of making forming, side-stiffening, panelling vertical ribs. The machine basically consists of two parts -

The die and forming device

The hydraulic power pack to operate the die

| SPECIFICATIONS | |

|---|---|

| MOTOR | 10 HP, 1440 RPM, 415 V, |

| 3 PHASE, 50Hz. | |

| TEFC INDUCTION MOTOR | |

| PUMP PRESSURE (kg/cm.sq) | 20/100 |

| CONTROL CIRCUIT | 110 V, 1 PHASE, 60 VA CAPACITY |

| CAN SIZE | AS PER CUSTOMER REQUIREMENT |

CONICAL EXPANDERS

The machine is used for forming conical shape bodies out of cylindrical form welded bodies. This machine essentially consists of an expanding mandrel which when expanded hydraulically gives the desired conical shape to body.

The round welded body is fed into the mandrel while mandrel is in closed position and on expanding the body takes final desired shape determined by the die. After stretching the mandrel comes back to close from thereby releasing the conical body.

The machine is self contained with a hydraulic power pack, hydraulic and electrical control elements, oil tank etc. with streaching tool. Pressure gauge and flow control valve facilitate setting of correct hydraulic pressure and speed of expansion. The machine is of compact design and will occupy minimum of space. The operator can sit and operate the machine with both hands free for loading and unloading.

| SPECIFICATIONS | |

|---|---|

| MOTOR | 15 HP, 400/450 V, 30 |

| 50 HZ, 1440 RPM, TEFC INDUCTION MOTOR | |

| PUMP PRESSURE(kg/cm.sq) | 20-140 KSC(50-2000 P.S.I) |

| CONTROL CIRCUIT VOLTAGE | 230 V, 10, 20 VA CAPACITY |

| MAIN SWITCH FUSE UNIT | 15 A, 3 POLE + NEUTRAL (can upto 5 Ltrs) |

| 30 A, 3 POLE + NEUTRAL (can above 5 Ltrs) | |

| FUSES | HRC FUSE 15 A (can upto 5 Ltrs) |

| HRC FUSE 30 A (can above 5 Ltrs) | |

| CABLE | 4 mm.sq.copper, 4 core (can upto 5 Ltrs) |

| 100 mm.sq.copper, 4 core (can above 5 Ltrs) | |

| OIL TANK CAPACITY | 100 Ltrs.(can upto 5 Ltrs) |

| 300 Ltrs. (can above 5 Ltrs) | HYDRAULIC OIL SPECIFICATION | TERRESO 52 TELLUS 27 OR 33 |

| APPROX. OIL QTY. | 100 Ltrs.(can upto 5 Ltrs) |

| 200 Ltrs. (can above 5 Ltrs) | |

| OVERALL SIZE | L 1050 W 625 H 1150 (mm)(can upto 5 Ltrs) |

| L 1200 W 900 H 1150 (mm) (can above 5 Ltrs) | |

| APPROX. WEIGHT | 350 kgs.(can upto 5 Ltrs) |

| 600 kgs. (can above 5 Ltrs) | |

Handle & Car Lug Welders

These machines are fully tooled up for specific jobs, for obtaining high-speed production, easy handling, consistent weld quality and cost saving.

Application Machine Model:

Ear lugs of paint can -- 15-02

Wire handle (chapdi) on can top (upto 5 kg.) -- 15-02

Handle on 5 ltr. rectangular can (one side at a time)-- 15-02

Wire handle (chapdi) on 15 kg. Container -- 15-03

Handles on 5 Kg. rectangular container -- 15-03-01

| SPECIFICATIONS | |||

|---|---|---|---|

| MACHINE MODEL | 15-02 | 15-03 | 15-03-01 |

| RATING KVA @ 50% DUTY CYCLE | 20 | 20 | 30 |

| DEMAND KVA(max.) | 60 | 95 | 95 |

| THROAT CLEARANCE (mm) Min.-Max. | 25-150 | 25-150 | 50-200 |

| ELECTRODE STROKE (mm) | 50 | 50 | 50 |

| Max. AVAILABLE CURRENT (SHORT CIRCUIT) (amps)+-5% AT THROAT DEPTH OF 300 mm | 13500 | 19000 | 19000 |

| NOMINAL ELECTRODEFORCE (kgf) @ 5.6 kg/cm.sq. AIR PRESSURE | 450 | 450 | 450 |

| AIR CYLINDER SIZE (mm) | 100 | 100 | 100 |

Press type Spot Welders

Press type Spot Welders are designed for extra ordinary versatility and are available with different styles of welding head arrangements. These air operated welders are designed for high speed production work to meet the needs of a vast number of metal fabrication shops. Automatic feed mechanism with X-Y axis and Rotary movements with PLC could be supplied for fast production

A variety of electrodes and toolings can be fitted to render them suitable for spot welding, simple projection welding, electro-brazing, hot riveting, electro-forging and upsetting.

Fully solid state electronic controls (Microprocessor based or CMOS based) are available for using with machine in order to obtain consistent and accurate weld results on a wide range of materials at a high speed automatic operation.

| SPECIFICATIONS | |

|---|---|

| MACHINE MODEL : SS | |

| RATING KVA @ 50% DUTY CYCLE | 20 to 75 |

| Max. AVAILABLE CURRENT (SHORT CIRCUIT) (amps)+-10% AT THROAT DEPTH OF 450 mm (Amps) | 27000 |

| THROAT CLEARANCE (mm) | 200 |

| ELECTRODE STROKE (mm) | 75 |

| NOMINAL ELECTRODE FORCE/Cyl.NB (@ 5.6 KSC AIR PRESSURE)THROAT DEPTH 450 (kgf/mm) | 1000 |